The Project

The project "Dream of Flying" is a Zeppelin inspired personal air transportation in the year 2031.

The problem we face now is that we are so limited to this two dimensional transport network, everything is on the same level, sharing the same road with thousands of other people, pushing, squeezing trying to find a way out. There is a simple solution - give people wings to fly.

I believe flying is the next evolution of transportation. We will step into an age when we take all that messy trails of tail lights and set them free into the sky.

The problem we face now is that we are so limited to this two dimensional transport network, everything is on the same level, sharing the same road with thousands of other people, pushing, squeezing trying to find a way out. There is a simple solution - give people wings to fly.

I believe flying is the next evolution of transportation. We will step into an age when we take all that messy trails of tail lights and set them free into the sky.

Thursday, 26 January 2012

Monday, 17 October 2011

Saturday, 15 October 2011

Monday, 26 September 2011

Friday, 9 September 2011

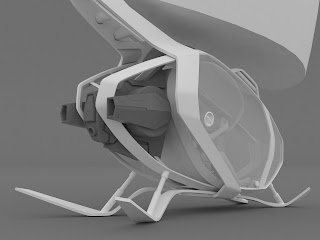

New Concept - Cockpit&Main body

In this new concept the passenger part of the airship is very important. It must have the quality of: light, compact, aerodynamic and visually appealing.

Concept1 is the one that appeals to me. The main structure/bones/chassis is a light carbon fibre structure that one piece. The passenger/pilot seat is a part of the chase which will be argonomically designed to fit all drivers. The tripod like landing gear will be another seperate piece, attached to the chassis by shock absorbers for stable landing. The cockpit part will be covered by transparent polycarbonate instead of glass for weight reduction.

Here is the rough clay model of the main chassis, just to give an idea to draw and develop on.

Mockup Prototypes - Configurations

Mockup 1 :

Here is the first mockup prototype for the new concept. It is to scale of 1:50. The wing/gas bag has a dimension of 13m in height, 5m max width and 2m max thickness. Around 100 cubic metres of volume in wing shape or less but should be more than enough to lift the airship.

This configuration has a single vertical structure to hold the gas bag in rotating axis, cord will be used to secure the gas bag to the cockpit and initiate the rotation action.

The single vertical structure is fragile, but it shouldn't be used to support much weight as the gas bag will be lighter than air, so in reverse the vertical structure is used to hang the cockpit. However other configuration should be tested further.

Mockup 2:

This is the alternative configuration that is more rigit in structure. 2 vertical structure securing the axis.

But the extra structure will add more weight. Also adding complication in folding down the structure for storage.

It certainly looks more secure, rigit and more safe then mockup 1?

Mockup 3: (Photo will be updated later)

Another single vertical structure configuration. The gas bag is devided into 2 parts. located on each side of the axis gives more weight balance than mockup 1.

Sunday, 4 September 2011

The Alternative concept

This is a quick sketch of the alternative concept in mind.

The cockpit is a very light structure consisting the seat, interface and the turbine engine. It is attached to a vertical structure which will hold the vertical gas bag in place. The ship transforms in mid air by pulling cables on one side of the gas bag, with the center of axis in the middel it will flip horizontal for gliding motion. The cables are supporting structures to hold the gas bag inplace. The gas will come externally to save weight and space. Then there will be infrastructure needed to inflate and deflate the gas bag.

Unresolved problem 1 - How to deflate and store the gas bag in relation to the gas bag structure. Since it need to be in the right shape of wings it will probable need a rigit structure. Solution in mind "1" is semirigit material that can be folded back, "2" profiles in between the gas bag that devide the gas bag in different section but the tension will hold the gas bag in shape. These profiles can be fabric aswell.

Unresolved problem 2 - How to colleps the vertical structure. Fold and colleps down? Is that going to compramize the rigidity of the structure?

Unresolved problem 3 - the rotation motion. It will need a axis to rotate. How to provide this axis. The rotational motion will be effected by wind and air friction. But the rotation can be utilized to navigate the airship while gliding.

The cockpit is a very light structure consisting the seat, interface and the turbine engine. It is attached to a vertical structure which will hold the vertical gas bag in place. The ship transforms in mid air by pulling cables on one side of the gas bag, with the center of axis in the middel it will flip horizontal for gliding motion. The cables are supporting structures to hold the gas bag inplace. The gas will come externally to save weight and space. Then there will be infrastructure needed to inflate and deflate the gas bag.

Unresolved problem 1 - How to deflate and store the gas bag in relation to the gas bag structure. Since it need to be in the right shape of wings it will probable need a rigit structure. Solution in mind "1" is semirigit material that can be folded back, "2" profiles in between the gas bag that devide the gas bag in different section but the tension will hold the gas bag in shape. These profiles can be fabric aswell.

Unresolved problem 2 - How to colleps the vertical structure. Fold and colleps down? Is that going to compramize the rigidity of the structure?

Unresolved problem 3 - the rotation motion. It will need a axis to rotate. How to provide this axis. The rotational motion will be effected by wind and air friction. But the rotation can be utilized to navigate the airship while gliding.

Subscribe to:

Comments (Atom)

About Me

- Runaway Prototype

- Runaway Prototype Design is a start up design consultancy based in Australia's creative capital Melbourne. Currently operated by industrial design professional/concept artist - Jet Shao a.k.a Runaway Prototype, ceramic artist/product designer - Lucy Liu a.k.a Runaway Bunny. Runaway prototype provide a wide range of design services from graphic design to designing products for everyday use. We develop our own product to suit the market. We also love to work with passionate entrepreneur with a big idea. So if you have a big idea love to see it become reality, don't hesitate to call us.